Laser Cutting

Tube laser cutting revolutionizes machining

In the early 1990s, Italian Adige launched the world’s first tube laser. Since then, tube laser cutting has revolutionized the processing of tubes with its unbeatable capabilities to save both time and tool costs. In principle, any shape can be cut in a fully automatic process. Instead of individual sawing, deburring, drilling, milling and punching, all steps can be performed in the tube laser in a single cycle.

The technology has developed at a fast pace and a technological leap that has really made a difference is the measurement method active scanning, an optical hole finding function where cameras measure the tube while driving and compensate for any deviations, which means that the tube laser cutting is both safer and more efficient.

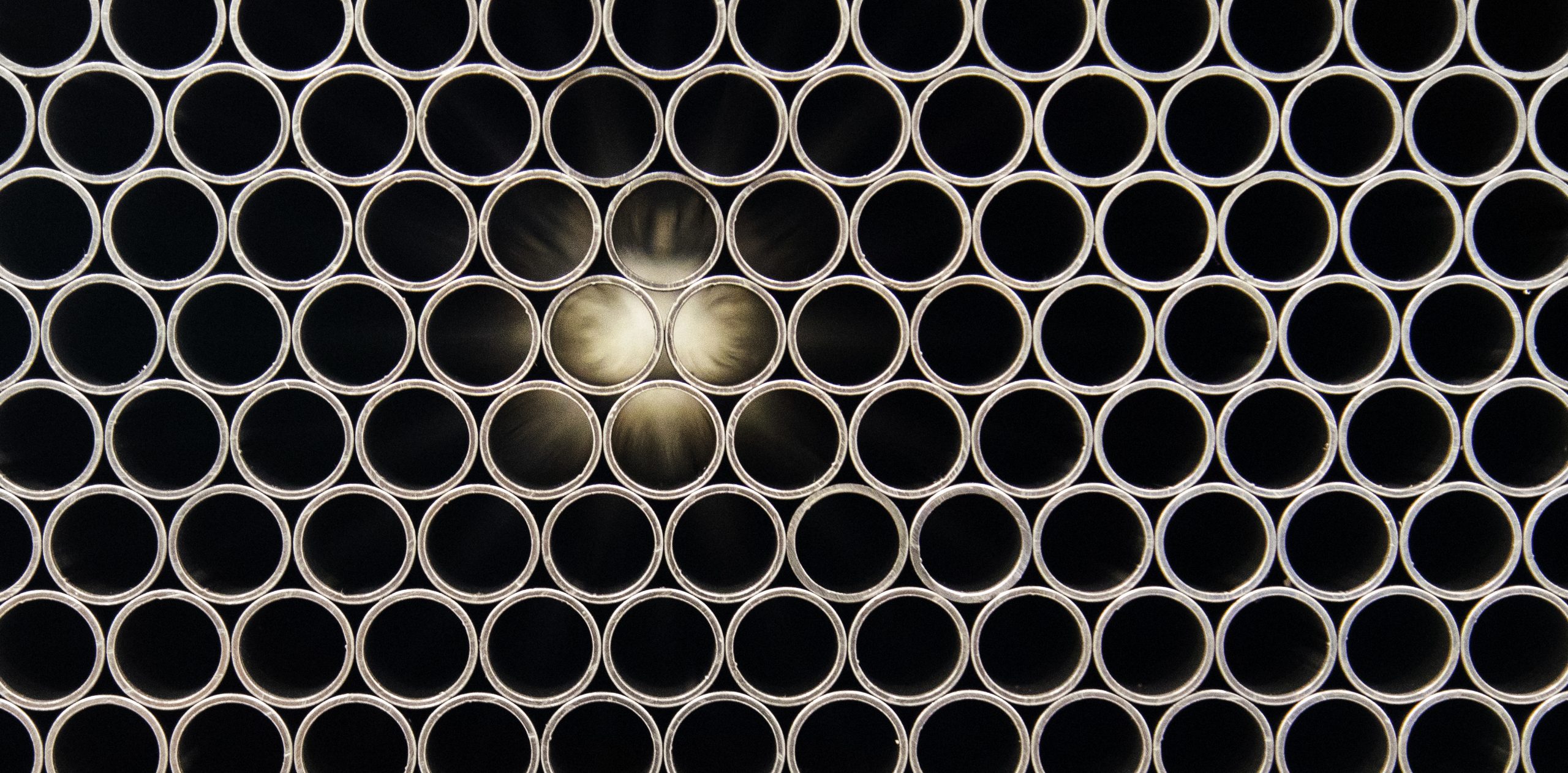

Steelnova can perform tube laser cutting of steel, stainless steel and aluminum such as brass and copper. The dimensions that our two tube laser machines handle are 12-140 mm in diameter for round tubes. For square tubes we can laser cut 12 × 12 to 140 × 140 mm. In both cases with wall thickness up to 8 mm. We can also cut profiles L, U and handle pipe lengths up to 8.5 meters into the machine and 4.5 meters out, which contributes to better material utilization and less wastage. Our tube laser machines have both oxygen (C02) and nitrogen (fiber laser) as laser source and we can laser cut in both 2D and 3D.