Tube Bending

Tube bending gives the desired shape

Tube bending is a common processing method in both the furniture industry and the automotive and engineering industries. Regardless of the type of tube and regardless of whether you work in different materials such as aluminum, copper and steel, tube bending provides opportunities to create exactly the shape you want. Pre-treated pipes can also be bent, and compared to splicing and welding pipes, bending is both cheaper and more efficient.

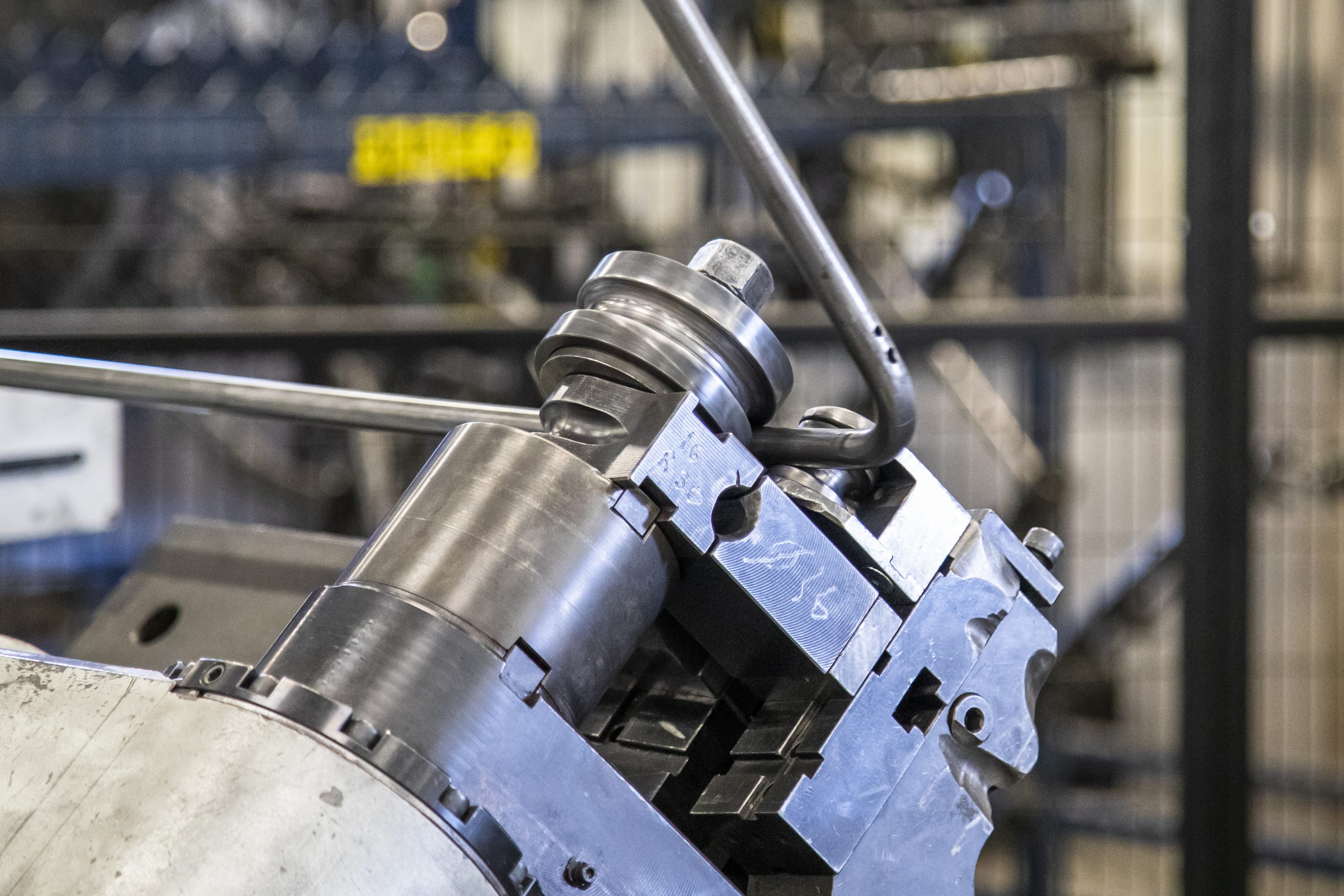

Steelnova offers tube bending in CNC-controlled machines, from 8 mm to 40 mm in diameter and the pipe magazines can handle pipe lengths up to 5 meters. The machines bend right and left, two-dimensional as well as three-dimensional, and roll pipes in the same cycle. The machines can also search for weld seams and reference holes for bending laser-cut blanks. To minimize set-up times, we can mount up to six tools simultaneously. Our five bending machines are fully automatic and one of them is also equipped with robotic picks for efficient handling of larger series. The machines from BLM Group have the most advanced technology for tube processing available on the market.

Steelnova’s machine park in tube forming is complemented by opportunities for eccentric pressing when you need to punch, shape and bend materials. Our capacity for eccentric pressing is 10-50 tons. In our eccentric press, we perform end machining before welding, we flatten, shape and shrink pipe ends and also handle countersunk holes.